Laminated Glass

About Laminated Glass

Laminated Glass features an interlayer bonded between two or more glass plies using heat and pressure. It is a type of safety glass that holds together when shattered. In the event of breaking, it is held in place by an interlayer, typically of polyvinyl butyral (PVB), between its two or more layers of glass. The interlayer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces.

Interlayer material available: PVB, SGP, XIR etc. Laminated glass also improves the acoustic performance.

Products Display

.jpg)

Feature & Performance

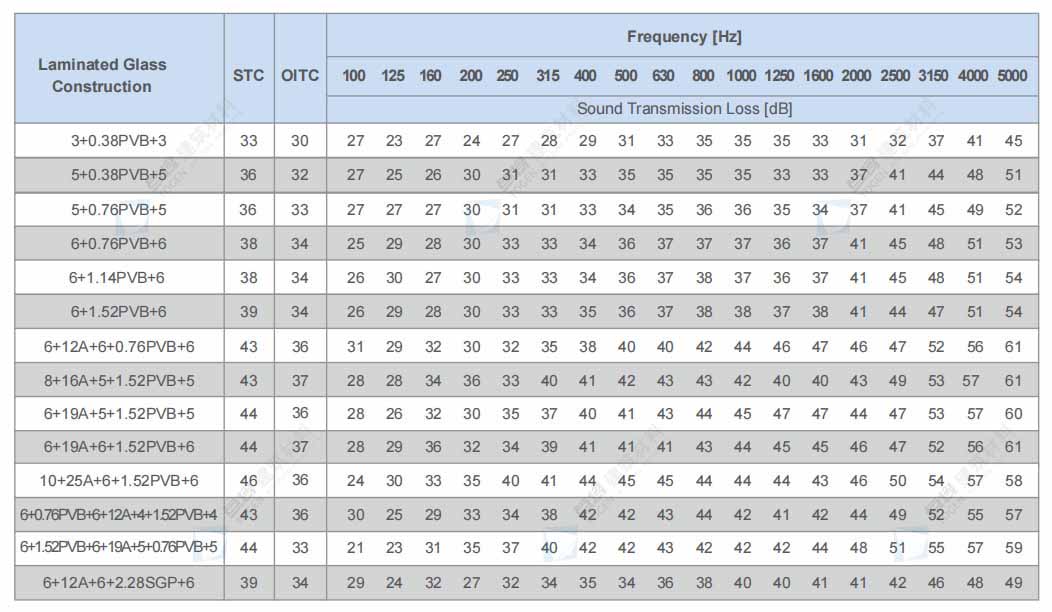

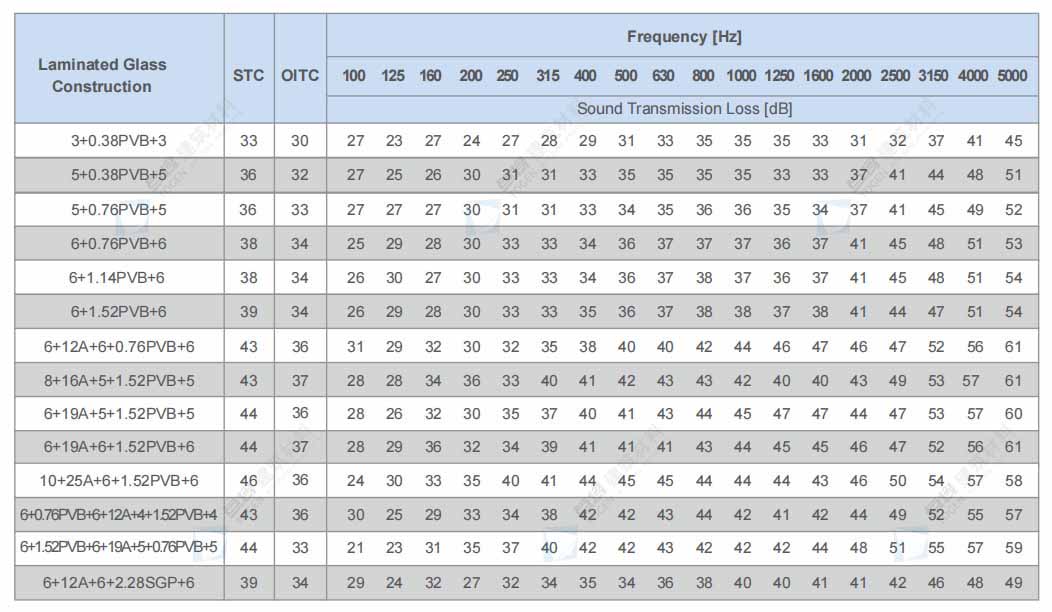

Acoustical Performance Data

(1)Security: laminated glass provides effective defense against vandalism, violent invasion. Multi-layers laminated can also be made for bullet proof or explosion proof glass.

(2)Safety: Once broken, the all the glass chips would still stick on the PVB and remain original shape, which brings no harm to human.

(3)Noise reduction: PVB membrane is excellent on blocking noise. (Reference Acoustical Performance Data)

Advantage of Laminated Glass

1.Raw Material

4. Strict Quality Control

7. Services

Process

Project Reference

Laminated Glass features an interlayer bonded between two or more glass plies using heat and pressure. It is a type of safety glass that holds together when shattered. In the event of breaking, it is held in place by an interlayer, typically of polyvinyl butyral (PVB), between its two or more layers of glass. The interlayer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces.

Interlayer material available: PVB, SGP, XIR etc. Laminated glass also improves the acoustic performance.

Products Display

.jpg)

Feature & Performance

Acoustical Performance Data

(1)Security: laminated glass provides effective defense against vandalism, violent invasion. Multi-layers laminated can also be made for bullet proof or explosion proof glass.

(2)Safety: Once broken, the all the glass chips would still stick on the PVB and remain original shape, which brings no harm to human.

(3)Noise reduction: PVB membrane is excellent on blocking noise. (Reference Acoustical Performance Data)

Advantage of Laminated Glass

1.Raw Material

- Own float lines with huge production capacity: 3000 tons/day

- Stock of various tinted glass for different client's demand

- 2. High Production Capacity

- 7 sets of Italy Bottero Cutting lines & 11 sets of Edging machine

- 6 Tempering lines with Heat Soak Test

- 4 Insulating lines

- 3 laminated glass production lines with capacity for producing safety laminated glass of 1000 ㎡/day, with thickness ranging from 2 to 19 mm

- Von Ardenne Coating Line with Bentler washer imported from Germany

4. Strict Quality Control

- Enquiry Stage: Technical evaluation by Tech. Dept. , to ensure the production feasibility and quality control ability

- Order Evaluation: Work out QC Plan for specific project and highlight the QC key points by Tech. Dept.

- Mass Production: Provide Daily Quality Inspection Report with detail photos

- Finished Products: Provide Final Quality Report with detail photos

- American Standard - ASTM C1376 SGCC

- Australian Standard - AS/NZS 2208

- Malaysia Standard - MS 1498

- Thailand Standard - TIS 1222-2560

7. Services

- Material solution consultancy during design stage

- Product proposal

- Detailed design and technical support from design to supply.

- Order tracking

- Financial support

- Quick action on NCR claim

Process

Project Reference